What are Hookless Rims?

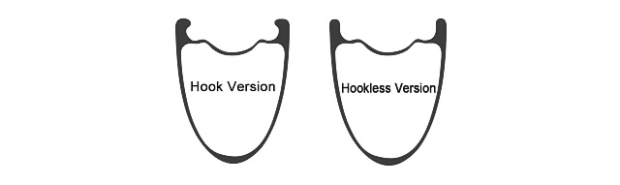

Hookless or TSS (Tubeless Straight Sidewall) rims are a relatively new thing in the performance road and gravel cycling world. The typical clincher (and early tubeless) rim utilizes a hooked, or crocheted rim, has tiny hooks that help to hold the tire on. This can be seen here:

Figure 1 © Light Bicycle

As with any time that a new technology is introduced, there are some growing pains. But hookless isn’t a new invention; nearly every other industry that utilizes pneumatic tires (automotive, airplanes, motorcycles, riding lawn mowers, and more) uses hookless wheels. Additionally, hookless rims do bring some desirable benefits. Some of these benefits, as highlighted by wheel manufacturers, include:

- More predictable and consistent compaction during the manufacturing process meaning stronger rims and higher impact resistance

- Optimized fiber to resin ratio meaning lighter rims

- No hooks mean a cleaner transition between the rim and tire (faster from an aerodynamic perspective)

The cycling industry in conjunction with international standards organizations have developed ISO and ETRTO standards to help guide both rim and tire manufacturers to have clear guidance with which to design and manufacture products in order to have more clear compatibilities. It took some time, but most manufacturers have brought their products in line with these standards, with most major tire brands now offering tires compatible with hookless rims.

Why is this conversation coming up?

Mainly, this conversation has circled back around because of a couple of recent incidents in the professional peloton where riders riding hookless wheels had tire blow outs resulting in crashes. I won’t speak to, or speculate on those events, as plenty of others far more knowledgeable than me have dissected those events, and the UCI has even launched an investigation into the matter. One of the areas where hookless rims have caught some flack though is regarding tire compatibility, tire size, and max tire pressure. So let’s look at those things.

Tire size and compatibility.

The ISO standards outline minimum tire sizes to be used with each internal width of rim in order to be considered safe and compatible. Outside of that, both rim and tire manufacturers also do in-house testing to ensure the safety and compatibility of their products. It’s always best to refer to those tire manufacturers’ approved tire lists or to check with the tire manufacturers to assess compatibility of their tires with hookless rims.

Max tire pressure.

This has probably been the biggest education point for customers getting hookless wheels for the first time. ISO and ETRTO standards guiding hookless/TSS rims have a max tire pressure of 72psi. This has also been the biggest complaint from many people regarding hookless rims. With clincher/crochet type rims, max pressure ratings also carried a fairly large safety margin. Historically, tires had a 200% safety margin. What that means is that if a tire is marked with a max pressure of 110psi, it had to stay on to the rim and not blow off up to a pressure of 220psi to pass the test.

With the standards guiding hookless rims and tires, that safety margin has shrunk to 110%, meaning a tire only has to be able to hold up to 79psi to be in line with these standards. This also introduces one of the biggest areas for concern with hookless wheels. For reference, many floor pumps are only accurate to 5-10%. Meaning if your pump happens to be one of those unlucky pumps that’s gauge is off by 10% and you inflate your tires to “73psi”, you may actually be inflating your tires to 80psi and be exceeding the safety margin of your tire. Ultimately the concern here is that this could cause the tire to blow off the rim while you’re riding, leading to a wreck.

IT'S NOT ALL DOOM AND GLOOM

We definitely don’t want to make this out to be all doom and gloom. The safety concerns that are being brought up regarding hookless wheels can be easily avoided with a few simple steps:

- When selecting a tire brand and model, make sure it’s compatible with your wheels

(you can find Zipp’s compatible tire list HERE, and Enve’s list HERE)

- You need to use compatible tires regardless of if you’re using inner tubes or have your tires set up tubeless

- When selecting a new tire, make sure the tire width that you choose is compatible with your wheels (see the tire compatibility lists above)

- Make sure you have a good quality floor pump, and don’t exceed 70psi when inflating your tires